This article introduces the characteristics and composition of diesel generator sets. Diesel generator sets are equipment that uses diesel engines as prime movers to drive synchronous generators to generate electricity, and have many advantages. It is mainly composed of an engine, a generator and a control part. The engine is a diesel engine with high power and good economic performance; the AC generator uses the principle of electromagnetic induction to output electrical energy; the automatic control system has a variety of protection functions. Generally, diesel generator sets are composed of multiple components and can be divided into fixed and movable types, and there are soundproof boxes to reduce noise. At the same time, it introduces the two types of diesel generator sets: common and standby, as well as the relationship between common power and standby power, and reminds us to consider the impact of the soundproof box on power.

A diesel generator set is a power supply equipment that uses a diesel engine as the prime mover to drive a synchronous generator to generate electricity. This equipment has significant advantages such as quick start-up, convenient operation and maintenance, low investment, and strong adaptability to the environment. It can be called an extremely practical power generation device.

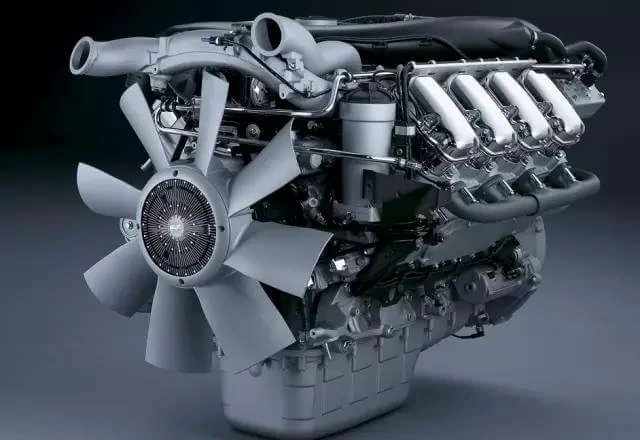

Part One: Engine

Diesel engines obtain and release energy by burning diesel. Their advantages are powerful power and excellent economic performance. The working process of a diesel engine is similar to that of a gasoline engine. Each working cycle goes through four strokes: intake, compression, power generation, and exhaust. However, since the fuel used in a diesel engine is diesel, which has a higher viscosity than gasoline and is not easy to evaporate, and has a lower auto-ignition temperature than gasoline, the formation of the combustible mixture and the ignition method are different from those of a gasoline engine. The main difference is that the mixture in the cylinder of a diesel engine is ignited by compression rather than ignition. When a diesel engine is working, air enters the cylinder. When the air in the cylinder is compressed to the end, the temperature can reach 500-700 degrees Celsius and the pressure can reach 40-50 atmospheres. When the piston approaches the top dead center, the high-pressure pump on the engine sprays diesel into the cylinder at high pressure. The diesel forms fine oil particles and mixes with high-pressure and high-temperature air. The diesel mixture burns on its own and expands violently, generating a powerful explosive force, pushing the piston downward to do work. At this time, the temperature can reach 1900-2000 degrees Celsius and the pressure can reach 60-100 atmospheres, thereby generating huge power.

Part Two: Alternator

Its working principle is to convert the mechanical energy of the prime mover into electrical energy output based on the electromagnetic induction principle that the wire cuts the magnetic lines of force to induce electric potential. The synchronous generator consists of two parts: the stator and the rotor. The stator is the armature that generates electricity, and the rotor is the magnetic pole. The stator consists of an armature core, evenly distributed three-phase windings, a base and end covers, etc. The rotor is usually a hidden pole type, consisting of an excitation winding, an iron core and a shaft, a guard ring, a center ring, etc. When a DC current is passed through the excitation winding of the rotor, a magnetic field close to a sinusoidal distribution (called a rotor magnetic field) is generated, and its effective excitation magnetic flux intersects with the stationary armature winding. When the rotor rotates, the rotor magnetic field will rotate with it. For each revolution, the magnetic lines of force cut each phase winding of the stator in turn, thereby inducing a three-phase AC potential in the three-phase stator winding. When the generator is running with a symmetrical load, the synthesis of the three-phase armature current will generate a rotating magnetic field at a synchronous speed. The interaction between the stator magnetic field and the rotor magnetic field will generate a braking torque. The mechanical torque input from the steam turbine/hydraulic turbine/gas turbine overcomes the braking torque to perform work.

Part Three: Automatic Control System

The system has the function of automatic start. When the city power suddenly fails, the unit can automatically start, automatically switch, automatically run, automatically transmit power and automatically stop; when the oil pressure is too low, the oil temperature or the cooling water temperature is too high, it can automatically send out sound and light alarm signals; when the unit is overspeeding, it can automatically shut down in an emergency, which plays a good protective role for the generator set.

Diesel generator type and power characteristics and the influence of mute box

Generally speaking, a diesel generator set is composed of a base, a diesel engine, a base tank, a generator set (i.e., a bulb), a controller (which controls and protects the generator set), a radiator (a fan for air cooling and a water tank for water cooling), a silent box, and other components. According to the different needs of different places, we divide the generator set into fixed and movable trailers. In order to reduce the noise emitted by the generator set and reduce the impact on people’s work and life, we have designed a silent box generator set based on domestic and foreign objects, that is, a metal box is installed outside the generator set, and sound-absorbing materials are attached inside to protect the generator set. Doors are set on both sides of the box to facilitate people to inspect and control the generator set. The silent box can not only reduce the noise emitted by the generator set, but also can be placed outdoors. The box is like a house, with sun protection and rain protection functions, which saves people the trouble of having no place to build a machine room.

Diesel generator sets are divided into common generator sets and standby generator sets, and the power is also divided into common power and standby power accordingly. The standard common power of each generator set is generally 80% of the standby power. If the generator set is needed due to power outage, please use the standby diesel generator set when using the national power grid at ordinary times; if it needs to run for a long time, please choose a common diesel generator set. If it is regularly maintained, the common diesel generator set can run for more than 300 days per year. The relationship between common power and standby power is: for example, if the user needs a 100KW diesel generator set, the common power of the standby 100KW diesel generator set is 100KW×80% = 80KW, that is, the common power of the standby 100KW diesel generator set is 80KW. If the diesel generator set is equipped with a mute box, the power of the generator set will also decrease, generally by about 10%. Therefore, when users purchase diesel generator sets, they should consider the power drop of the mute box.